The Automatic Moving Plate Chamfering Machine is specially designed for chamfering, milling, and chamfering various metal plates before welding. When machining small inserts, the machine is fixed and the inserts are automatically fed for processing; When processing large inserts, the plates are fixed and the machine automatically moves along the edge of the plates to be processed; When the working height is non-standard, the machine can be hung without a chamfering base. This machine adopts milling method. It is a powerful and widely used equipment for chamfering various grades of steel and other metal sheets. It is small in size, light in weight, easy to move and easy to operate. It is a necessary production equipment for the nuclear industry, shipyards, pharmaceutical equipment, pressure vessels and other industries.

Product Features

1. Cold working method without changing the material of the steel plate;

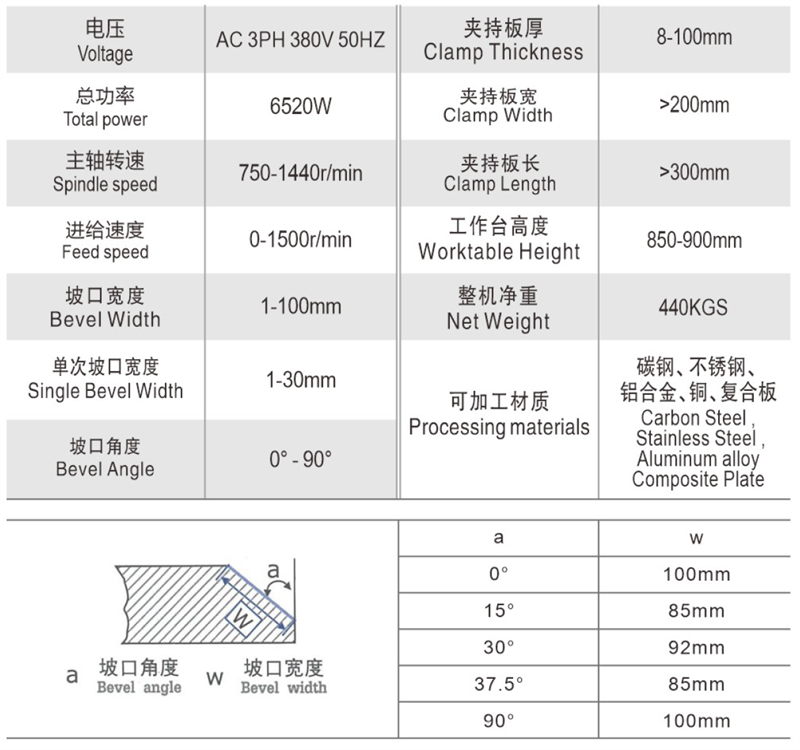

2. The groove angle can be adjusted arbitrarily from 0 to 90 degrees;

3. Clamping plate thickness: 2-100mm, maximum slot width 100mm;

4. Machined grooving shapes: type V, Y, K, X;

5. Milling machining, the surface roughness can reach Ra3.2-Ra12.5;

6. Double digital display control system, cutting speed and feeding speed are adjustable;

7. Suitable for processing engineering profiles, such as carbon steel, stainless steel, alloy steel, cast iron, etc.;

русский

русский