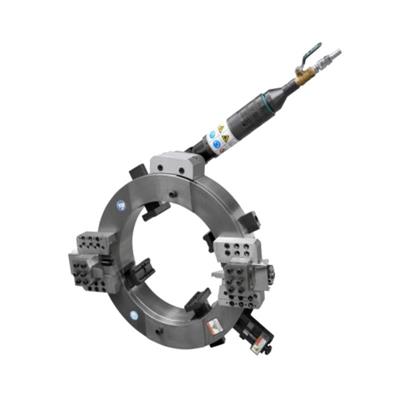

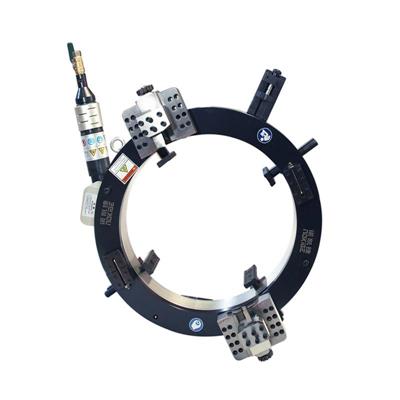

● Self-centering, no need to manually adjust the concentricity and perpendicularity. Four lamps are installed synchronously and provide a high effect.

● New type of regulation, save the replacement step of the flow unit.

● Adopt a new synchronous feeding mechanism to ensure uniform feeding, the tool bits have a longer service life.

● Easy to set up, operate and maintain.

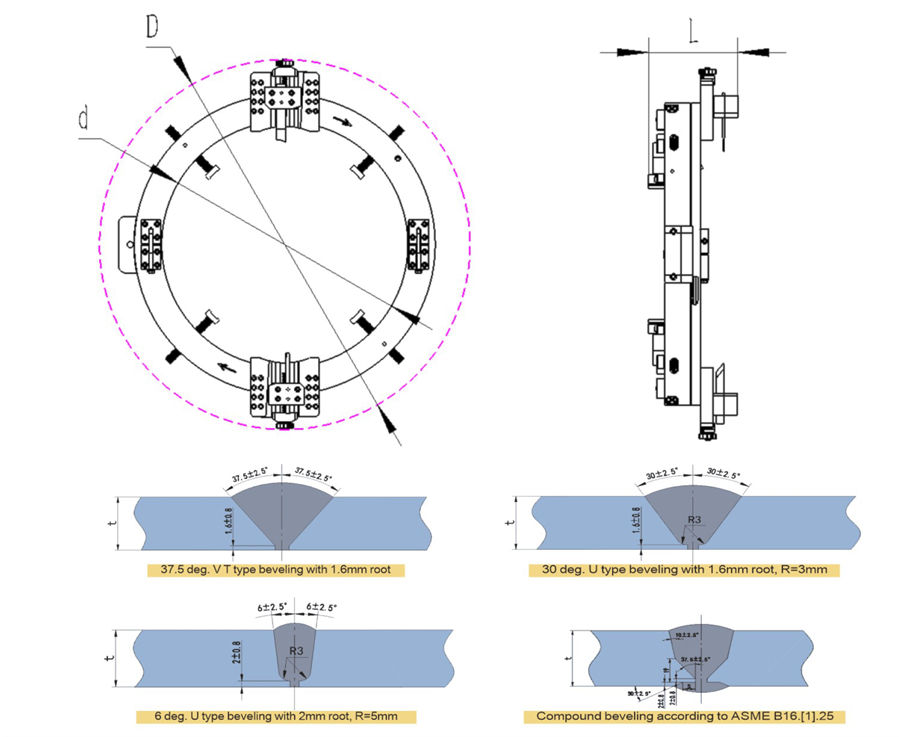

● Cutting and chamfering are done at the same time, high working efficiency.

● Cold processing, no spark, will not affect the material.

● Perfect working accuracy, no burrs.

● The well-adapted installation of the split system allows you to adjust the speed according to the working conditions.

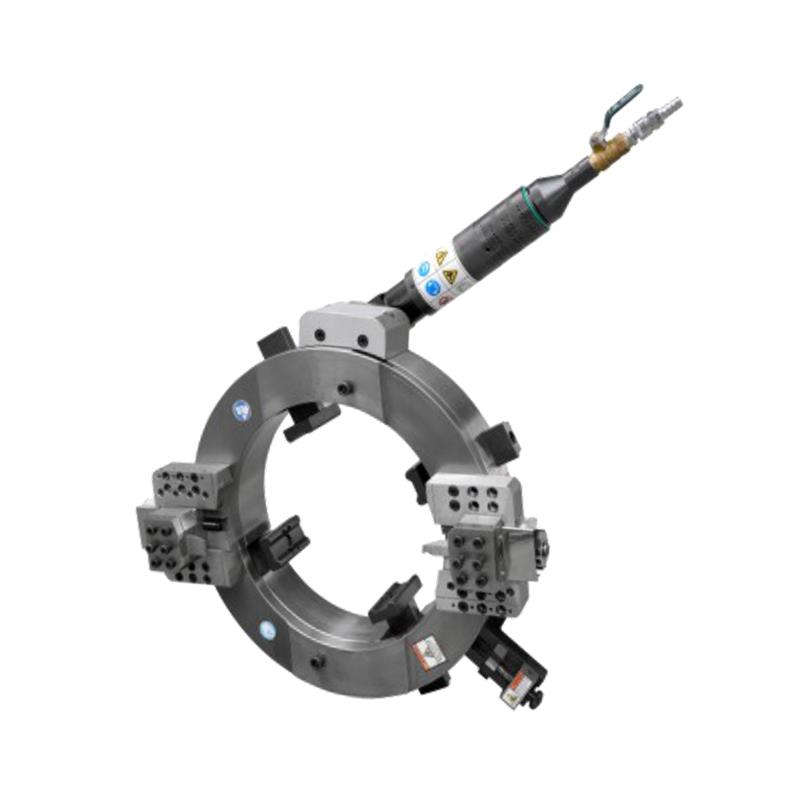

A standard external cutting and chamfering machine sets the processing range in accordance with international standards for pipelines. It can perform single cutting or single chamfer processing on pipes, containers, and flanges of various specifications. It can also complete chamfer cutting and processing at the same time, as well as complete complex chamfer processing and flange surface treatment. It is thoughtfully designed and very easy to install and operate. The body of the machine is a split ring structure, which is very convenient to disassemble and combine. It can be installed anywhere in the pipeline. It is a mobile pipe cutting and chamfering machine, suitable for cutting and chamfering various grades of carbon steel, stainless steel, alloy steel and other metal materials, as well as special hard structural materials. It is widely used in pipeline installation projects and emergency pipeline repair operations in oil, chemical, gas, food, boiler, pharmaceutical, nuclear power, facility construction and other industries.

русский

русский