Electric (NKVE)

Motor Power: 1800W/2000W

Working Voltage: 220-240V

Operating Frequency: 50-60Hz

Working Current: 8-10A

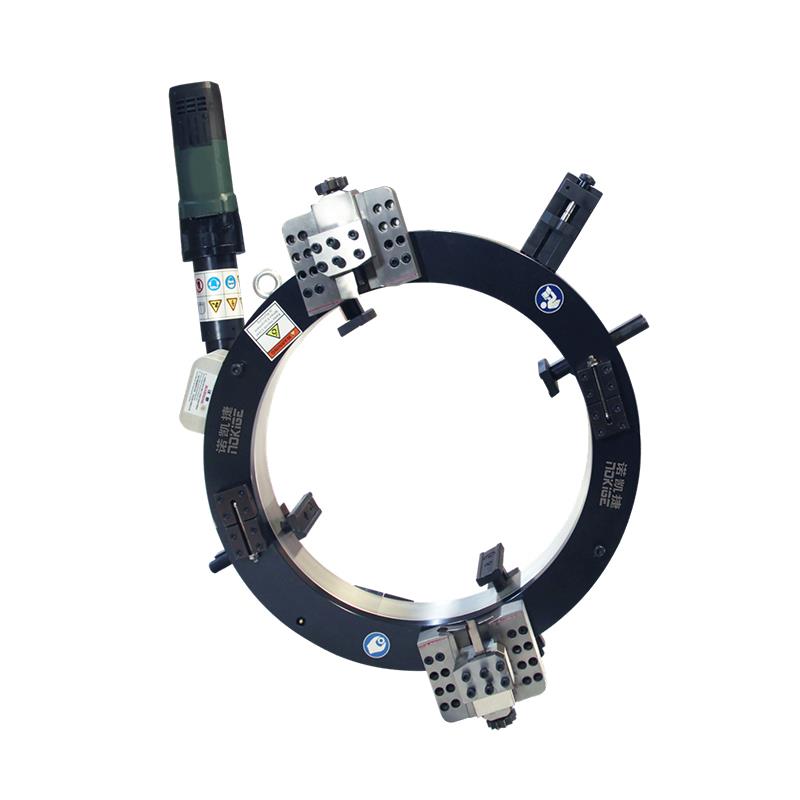

The standard external cutting and chamfering machine sets the processing range in accordance with international standards for pipelines. It can perform single cutting or single chamfer processing on pipes, containers, and flanges of various specifications. It can also complete chamfer cutting and processing at the same time, as well as complete complex chamfer processing and flange surface treatment. Its design is ingenious, and the installation and operation are very simple. The body of the machine is a split ring structure, which is very convenient to disassemble and combine. It can be installed anywhere in the pipeline. It is a mobile pipe cutting and chamfering machine, suitable for cutting and chamfering various grades of carbon steel, stainless steel, alloy steel and other metal materials, as well as special hard structural materials. It is widely used in pipeline installation projects and emergency pipeline repair operations in industries such as petroleum, chemical, natural gas, food processing, boiler houses, pharmaceuticals, nuclear power and facility construction.

Product Features

1. The diameter of one machine is 6 inches;

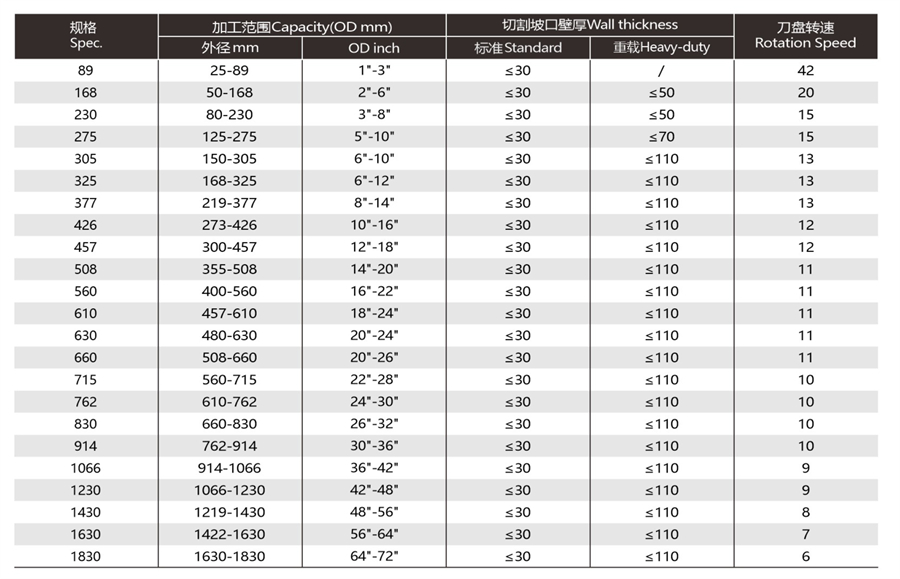

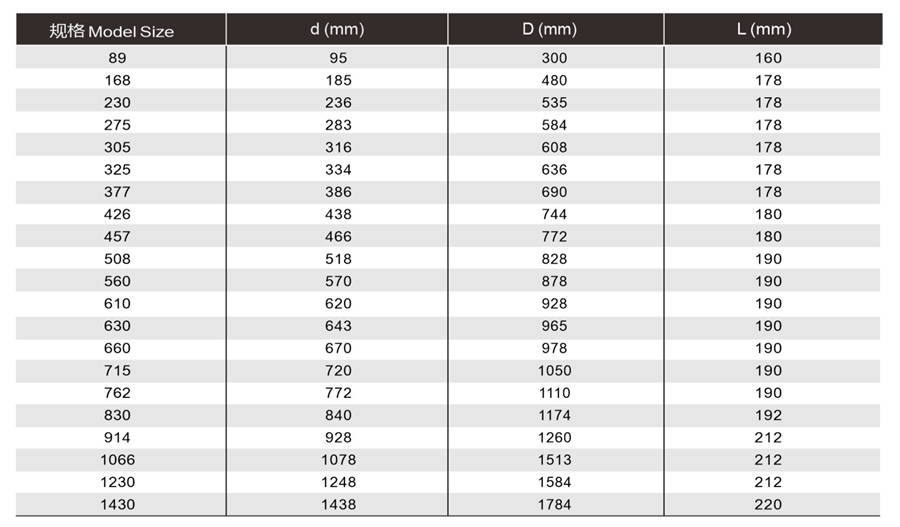

2. Dozens of specifications, can process pipes with a diameter of 25-30000mm;

3. One-time clamping, cutting and chamfering are done at the same time;

4. Completely cold cutting method, does not change the pipe material;

5. Automatic feeding, no manual adjustment required, high efficiency, high quality;

6. Split hinged body, petal installation in any position of pipeline;

7. The fixed ring is made of aluminum alloy or alloy steel, and the moving ring is made of alloy steel;

8. Optional processing accessories are optional to improve productivity and expand processing capabilities;

9. Optional drive mode: electric, pneumatic, CNC, hydraulic;

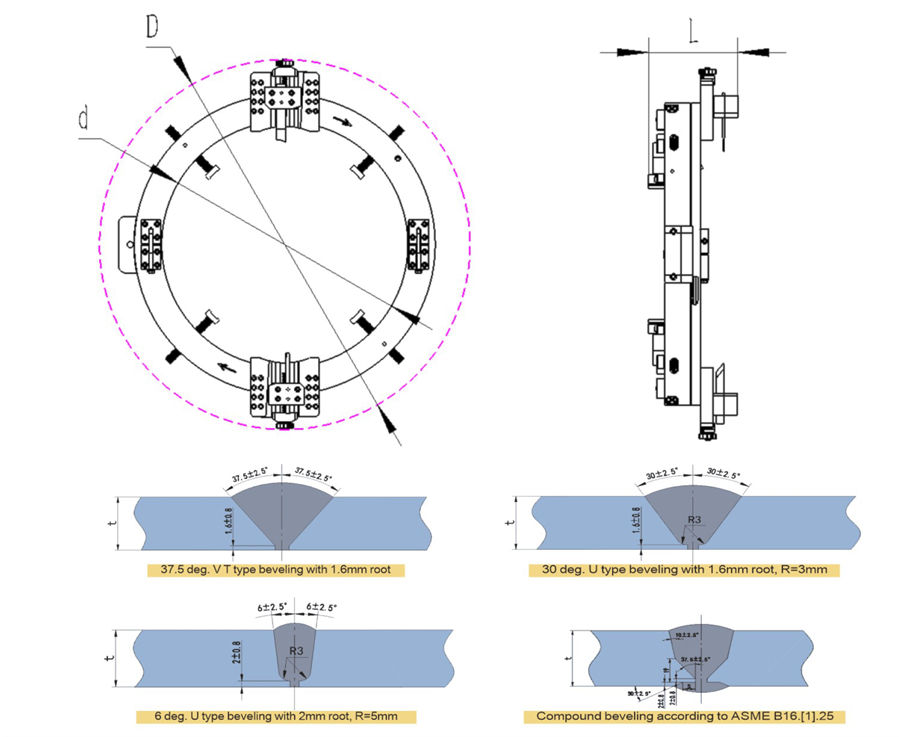

10. Machined chamfer shapes: U-type, V-type, J-type, double V-type and composite;

11. The installation method of the drive head is direct connection and optional orthogonal to avoid interference and meet the requirements of optimal position installation.

русский

русский