The Stationary Pipe Cutting and Beveling Machine is a complete pipe cutting and chamfering machine designed for batch pipe production. It is a reliable pipe cutting and chamfering machine. It is driven by a powerful variable frequency motor, electric clamping system, automatic centering, and the main machine can be raised and lowered. It is suitable for grooving of various shapes, such as U, V, J, Y, etc., for pipes made of various materials, such as carbon steel, stainless steel, and alloy steel. It has high processing speed, high precision, good grooving quality, and easy operation. It can be equipped with logistics systems such as fixed pipe length and pipe transportation to form a prefabricated pipe production line.

Product Features:

1. Completely cold cutting method, does not change the pipe material.

2. Simple mechanical button operation, simpler and more convenient operation;

3. Clamping electric clamping system, automatic centering, automatic clamping;

4. Mechanical automatic feeding, manual retraction;

5. Built-in recirculating water cooling system to increase the service life of tools and machine tools;

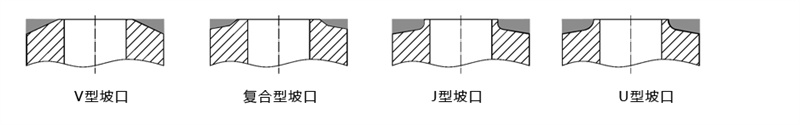

6. Machined cutting groove shapes: U-type, V-type, J-type, double V-type and composite type;

7. Disposable clamping, cutting and grooving at the same time, also can be single, single bevel or shear and bevel on both sides at the same time;

8. The main machine is equipped with a lifting system, which is perfectly adapted to the use of different diameter pipes on the same logistics line;

Processing functions:

1. Pipe cutting;

2. Internal and external chamfers at the end of the pipe;

3. Flat pipe end;

4. Simultaneous bevel cutting;

5. Complex bevel;

6. Boring;

7. Repair of the outer wall of the pipe;

8. Grooving

Groove Type

V-type chamfer, J-type chamfer, U-type chamfer, double chamfer, combined chamfer

русский

русский